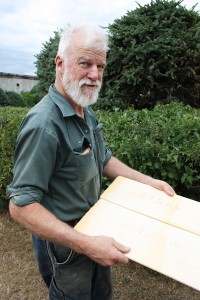

Larry Stamm’s workshop is where the music happens.

Actually most of the sounds are not very musical: mostly it’s chiselling, band sawing, and torching.

“It all starts with a chunk of wood,” Stamm says in his McBride, B.C. workshop, holding up a spruce plank that looks little more than a scrap. It will eventually be the sound board of a guitar, only millimetres thick, smooth and even.

He fits one long skinny plank into a vice.

“Canoes and ships and that – they’re all bent with heat and steam,” he says, demonstrating how he heats each plank to shape it to the side of a guitar.

Stamm has been making wooden stringed instruments for 15 years, after learning the craft from a guitar-making farmer in Saskatchewan. He now sells instruments to musicians all over the world. He only makes 12-15 a year, which sell for several thousand. If they get bumps, he irons them. If the sound is off, he runs a hand through the chisels on his wall searching for the perfect one to fix them.

It wasn’t Stradivarius that inspired him to begin his work as a luthier, however.

“I got beat up by a heifer and I tried to think of something I could do if I was incapacitated,” he says.

Stamm wasn’t permanently disabled by the accident, but has since perfected many designs for guitars and other wood instruments which are unique to him.

Making an instrument is more about physics than music. He says the first thing you start with is the height of the soundboard. When he speaks about the instruments he uses terms like “torque” and “cycles per second,” words you’re unlikely to see on a symphony score. He says a lot of the design is based on tradition, and not necessarily on the most pleasing sound. High-class violins for example are made of European Spruce and Maple, because that is the wood available in Italy when they first started making violins. But Stamm says birch is a better wood.

Building an instrument is understanding the duelling pressures of stiffness, lightness and vibration. Like a tight-rope between trees, the vibrations on the strings can put the pressure of a hurricane on the neck.

“If you build it too weak, it will sound good, but it’ll eventually implode,”

Outside the shop is a pile of wood taller than he is. That stack is the beginning of hundreds of violins, mandolins, fiddles, bouzoukis, guitars violas, and maybe a cello. The wood is birch, douglass fir, cedar and aspen. Stamm uses almost all local wood that he either culls himself or buys from a logger. The different wood affects the tone – but so does each tree. The size of the body of the instrument dramatically alters the sound too. A tiny guitar sounds tinny, just as a mandolin can’t support deep base notes, if tuned lower.

“The whole thing is like a tuned box,” he says. “I kind of have an idea when I start where I want those frequencies to be and how thick the soundboard has to be, and the back has to work in concert with it.”

Often he still has to shave off parts to get it tuned right.

“This is my own design,” he says grabbing a thin plastic stencil of a guitar with lines drawn across it to show where the support will go inside the instrument. “The simple explanation is you glue up a bunch of pieces of wood together until it becomes an instrument. The complex explanation could take years.”

Every piece is weighed and tested for stiffness. He draws out his new designs on paper. Fitting the neck onto the instrument is the most important, he says. If the neck is crooked it can ruin the instrument. He’s had to give up on a few instruments he’s started. He says violins are by far the hardest because they are small and every stroke must be more refined.

Canada has proportionally more instrument makers due to the easy access to good wood, Stamm says. It’s easier to ship an instrument than it is to ship wood, he says. The Robson Valley, where Stamm lives between Jasper and Prince George, is a great spot for available wood suited to instrument making. Hand-made instruments are the most valuable to professional musicians, because they can be customized in design to suit the musician. This makes luthiers like Stamm known around the world.

Gordon Carson of Valemount, B.C. has been harvesting wood and selling it to instrument makers for many years. A logger most of his life, a friend contacted him about getting wood for a mandolin. He brought down a truckload of wood to Vancouver and Victoria and sold the entire stock.

After that he put in an ad in an instrument-makers magazine, but he says he gets most of his business by word of mouth.

Carson says spruce is the best wood for a mandolin, but the wood also needs to be aged at least five years for an ideal sound. The ageing process changes the properties of the wood so that it better conducts sound.

“You need wood from a lot of trees to be able to match the right wood to the right instrument maker,” he says.

Instrument makers will often specify how many grains to the inch they prefer in the wood they order from Carson. He sells wood for violins, banduras, alp horns and North American flutes among others.

Another local resident, Keith Berg of Dunster, makes French Horns. He says the best instruments are always made by hand.

Stamm says he enjoys creating a thing that can make beautiful sound. Sometimes he will listen to the musician play a stringed instrument he once carved from a tree and held as a chunk of wood. When he listens he will hear not scales, but vibration, density, and lightness – his musical score.